LED Display Screen is more and more popular in market, especially outdoorled display with large size for advertising, large size means highpower consumption.

A dozens of square meters led video wallusually reach tens of kilowatts, energy saving will be one of the mostimportant trends in the future

How energy saving LED display can makeit?

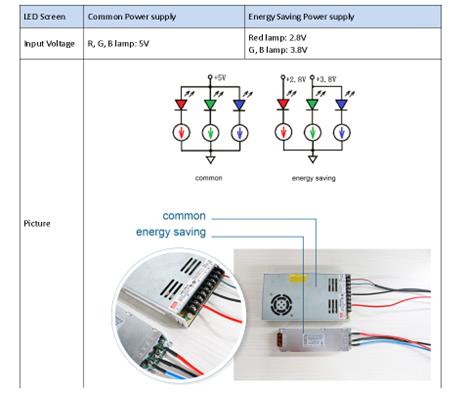

1. Low Power Supply Design For LED Display Module

The best working voltage of LED Lamp is about 1.8V-2.8V(Red lamp) and2.8V-3.8V(Blue and Green lamp). However, the supply voltage provided by thetraditional LED Display is much higher than its required working voltage. So itcan reduce unnecessary losses after adopting the new-designed power supply.

For the Traditional LED Display, the power supply adopts a single-voltageunified power supply of 5V DC. But the energy-saving power supply is based on adual-voltage power supply design. RED LED Chip with 2.8V DC power supply, GREEN,BLUE LED Chip with 3.8V DC Power Supply. It means the R, G, B lamp will workunder its normal working voltage.

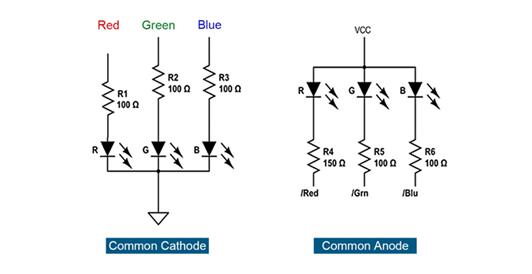

2. Different Design of PCB Board

The Energy-saving LED Display also has its own unique PCB board design,with the energy-saving power supply to achieve accurate voltage distribution. Inother words, the lamps can be swimming at the ideal work environment, the PCBequal the swimming pool and the power supply equal the water. This design canalso be called “Common Cathode”.

On the contrary, normal LED Display, we call it “Common Anode”. As it usesa unified power supply design, no matter it need more or less voltage. That’swhy the energy-saving led screen also called by Common CathodeEnergy-Saving LED Display.

3. Different Design of Driving IC

Another indispensable element is the Driver IC. The innovation of Drive ICis mainly reflected in its low switching voltage and common cathode design, theformer can save energy by 5%-8%, the latter can save energy by 20-25%.

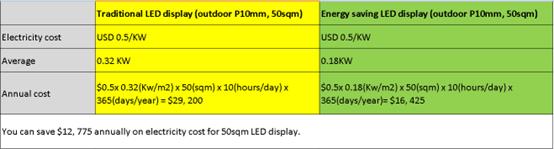

Calculate as 50sqm outdoor led display ( Daily working time 10h,cost USD 0.5/KW)